01 How Oxygen Absorbers Work?

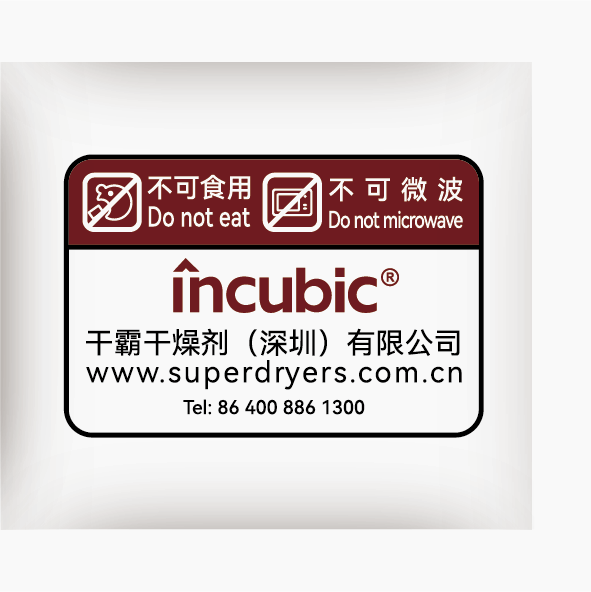

An oxygen absorber contains iron-based compounds that initiate a chemical reaction when exposed to air. Once sealed inside the package, the packet begins absorbing oxygen and continues until saturation is reached.

This reaction lowers the internal oxygen level to below 0.1%, significantly slowing oxidation, mold development, and spoilage. Because the contents remain dry and inert, oxygen absorber packets are ideal for food packaging and do not alter taste, smell, or texture.

02 Application of Oxygen Absorbers

Oxygen absorbers are used to protect packaged items from oxygen-related damage and deterioration. These oxygen scavenger packets offer targeted protection in sealed environments where air exposure could affect product integrity.

Below are some of their most common applications across different industries:

- Dry Food Products: Common in packaging for grains, beans, pasta, spices, and dehydrated meals to preserve taste, texture, and aroma.

- Meat and Jerky: Maintains natural color, prevents rancidity, and slows down spoilage in vacuum-packed or sealed meat products.

- Pet Food and Treats: Extends shelf life while protecting nutrients, fats, and flavors from oxidation inside sealed packaging.

- Medical and Diagnostic Kits: Protects reagent strips, testing components, and sterile packaging from oxygen exposure during storage and shipping.

- Nutraceuticals and Supplements: Preserves potency in capsules, powders, and tablets by reducing oxidation and moisture-related breakdown.

- Electronics and Metal Components: Reduces corrosion risk by limiting oxygen exposure in packaged metal tools, chips, and small assemblies.