SUPER DRY desiccants effectively remove moisture from inside containers and packaging. Keepings goods dry and safe from moisture damage. SUPER DRY desiccant bags are engineered to absorb moisture from the air, thus reducing the humidity in a controlled environment like poly bags, carton boxes and containers.

During transportation or warehousing, moisture can enter the containers and product packaging. Sudden temperature changes, which are common during sea transport, increase the risks of container rain or cargo sweat, which may result in corrosion, products infected with mold/mildew, bad odor, crushed and collapsed packaging. To avoid those moisture induced risks to any type of cargo, it is essential to take preventive measures ensuring the goods arrive at their destination in perfect condition.

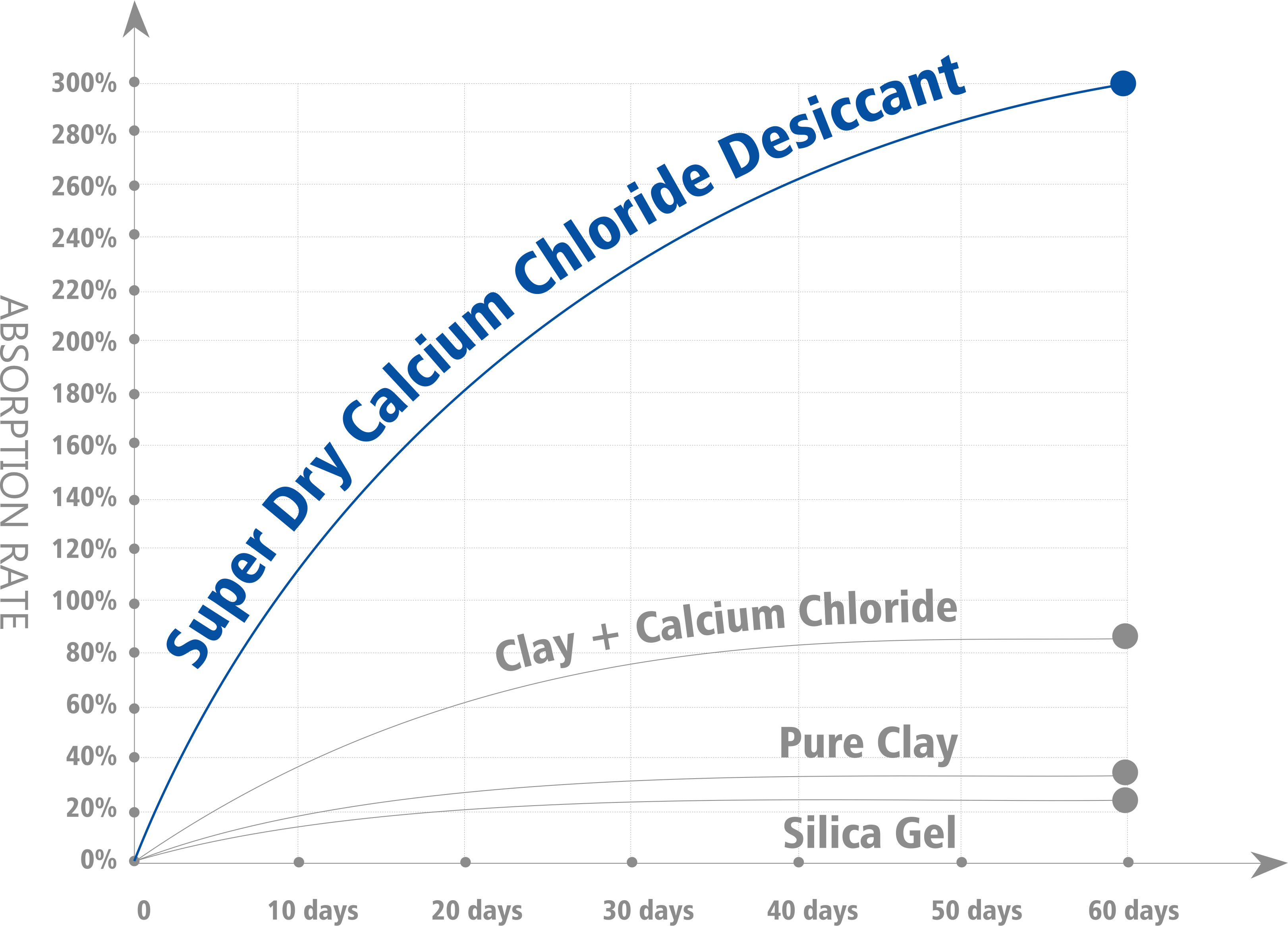

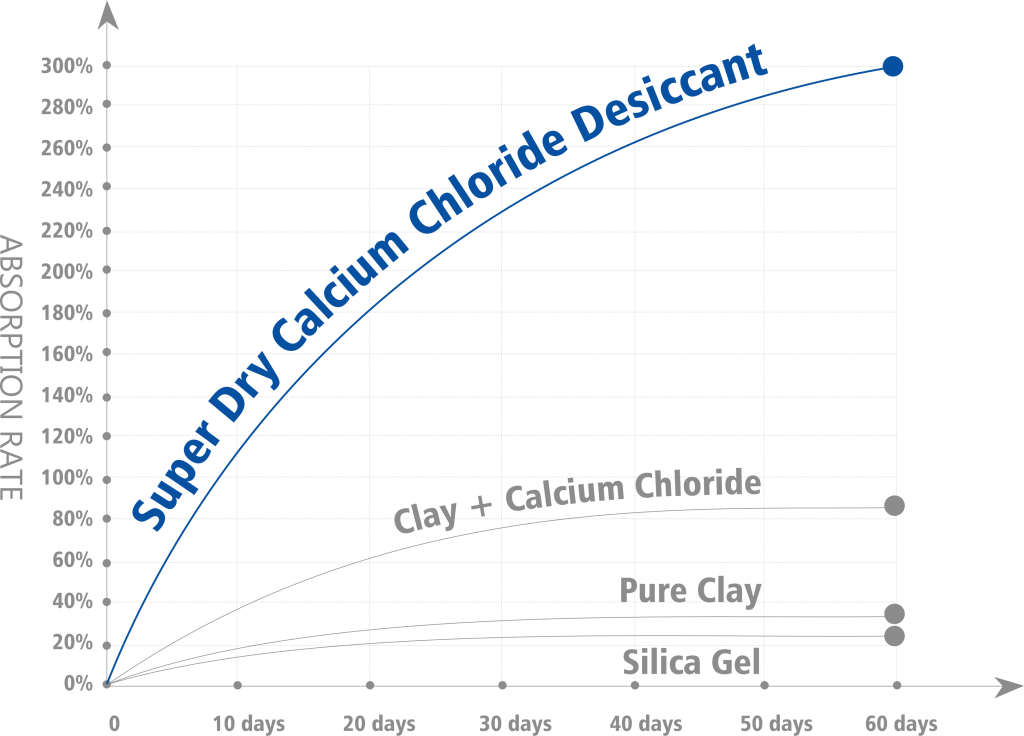

Compared to the classic desiccant types of Silica Gel and Clay, SUPER DRY desiccants provide the necessary safety from moisture damage during extended intercontinental sea shipments.

SUPER DRY desiccants have a verified absorption capacity of more than 300% of their dry weight and continuously absorb moisture for up to 90 days in temperature conditions ranging from -5°C to +90°C.

Whereas the adsorption capacity of Silica Gel and clay is limited to between 25% and 40% of their dry weight, reaching saturation point between 3 and 7 days after application with a temperature application range limited to between 15°C and 30°C. Silica gel or clay desiccants therefore do not provide sufficient protection from moisture damage during sea transport.

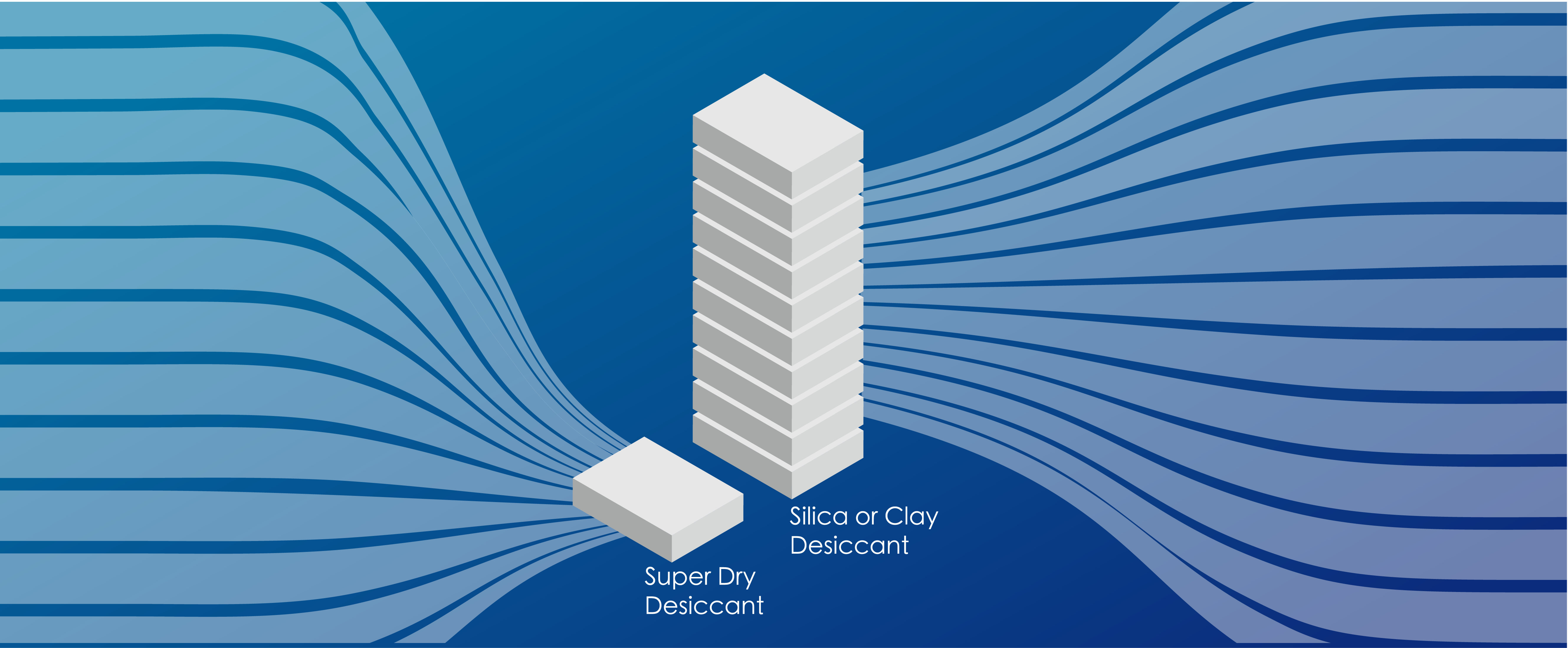

SUPER DRY desiccants absorb 10 times more moisture than Silica Gel or Clay and are applicable within a wider temperature range. SUPER DRY desiccants are the superior solution for moisture damage prevention inside containers, transport boxes and product packaging. Keeping your cargo perfectly safe from moisture damage risks.